6 Minutes

6 Minutes

Boosting Performance in Manufacturing with Business Intelligence

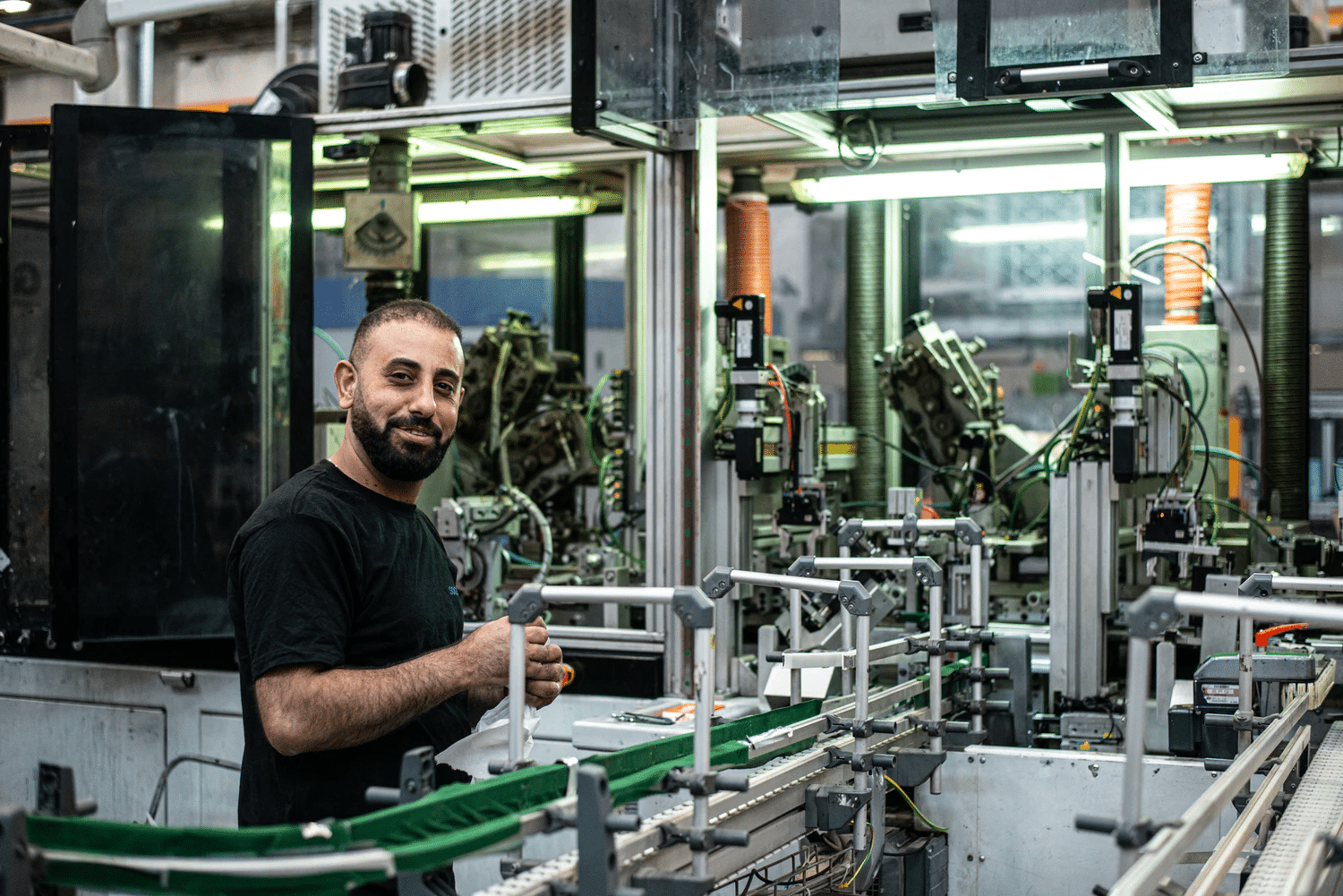

Manufacturers today face increasing waves of uncertainties and competition globally, forcing them to unlock value and maximize profitability across their operations.

From adhering to tight production schedules to the careful sourcing of raw materials, companies are currently doing their best with traditional strategies to max out their operational capabilities amidst an environment of slowing growth.

Additionally, the COVID-19 pandemic has brought about new challenges for manufacturers. A recent survey by McKinsey showed that manufacturers in Asia are struggling with sudden raw material shortages together with steep drops in demand and worker unavailability.

Manufacturers will need a better way to effectively increase the productivity of their operations to compete effectively amidst these challenging times.

This can be achieved by leveraging the huge amounts of proprietary data being generated and analyzing them to gain valuable insights.

Utilizing business intelligence and conversational analytics, this streamlining can be done in a data-driven manner, eliminating any guesswork and lengthy trial & error testing.

Solving the Biggest Challenges in Manufacturing

Customers today demand products of the highest quality that are delivered to them fast.

That means manufacturers will have to be increasingly on the ball, maintaining production up-time while still being flexible to ramp up or scale down production volume.

With COVID-19 disrupting global trade, new complex problems such as the need to create a safe environment as well as supply chain disruptions will force manufacturers to innovate to get left behind.

Additionally, organizations will need to find a way to optimize both their production and manufacturing costs, especially key components that can be controlled such as:

- Material costs

- Equipment maintenance costs

- Labor costs

Because manufacturing costs are closely tied to the level of production, optimization efforts will scale, allowing for small changes to snowball to big money or time savings for manufacturers.

Utilizing the manufacturer’s data, business intelligence will be able to deliver strategic insights to decision-makers. This allows them to find ways and execute strategies in order to lower the per-item cost and to minimize downtime so as to drive more profit with every production run.

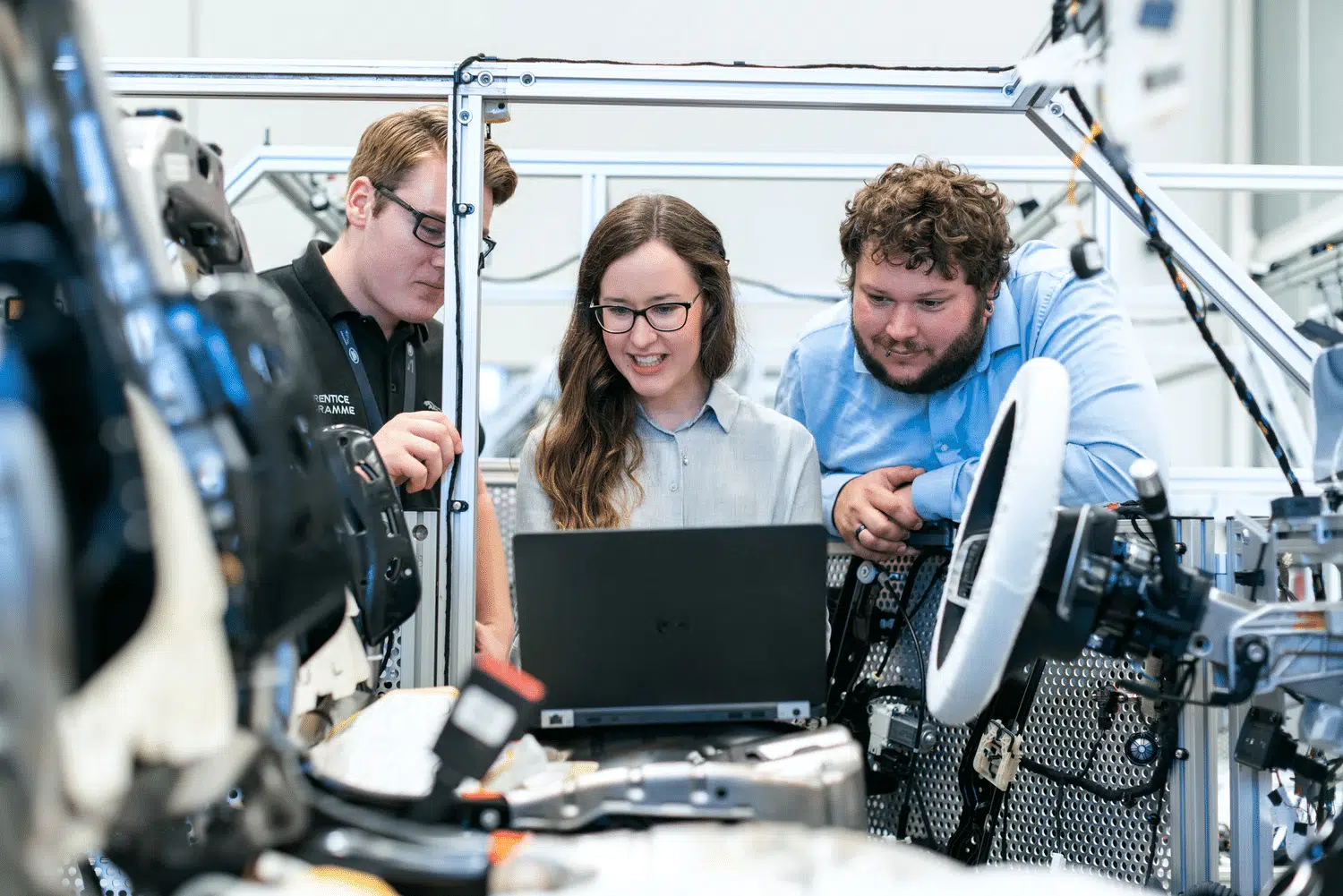

The Need for a Manufacturing Business Intelligence Solution That Promotes Data Democratization

While many current business intelligence tools in the market today do help manufacturers gain more insight into key metrics such as Production Volume, Down Time, and Overall Operations Effectiveness, this is not enough.

The analysis typically done by data and analytics teams is outdated and obsolete by the time it reaches the desks of decision-makers on the production floor.

From creating better demand forecasts to a more accurate machinery utilization models, manufacturers require more agility to derive insights in a friction-free manner.

Through conversational analytics-driven business intelligence, leaders across the organization can simply ask questions intuitively as they would in a normal conversation to gain insights from their datasets.

6 Ways Business Intelligence & Analytics Can Help Manufacturers Innovate & Stay Competitive

Business intelligence and analytics allow leaders to not only gain a strategic view across their manufacturing operations but also quickly identify key areas that will need optimization.

From the production floor to product pricing, business intelligence in manufacturing helps gain insight into their data to drive growth and maximize profits to stay competitive.

1) Decrease in Production Downtime

Machinery and systems in manufacturing are prone to a whole host of situations that can cause stoppages and breakdowns, leading to precious production time lost.

In fact, according to Aberdeen Research, around 82% of companies experienced unplanned downtime over the past 3 years that could cost the organization beyond $250,000 an hour!

This not only causes financial strain, but also a potential loss of trust with customers and suppliers.

As processes get more complex and an ever-increasing need to maintain a constant stream of production, manufacturers will have to leverage the power of their datasets – age, speed, output, heat etc., – to preemptively predict their failure.

This preventive maintenance scheduling is only possible by incorporating big data analytics together with business intelligence to provide operational and maintenance teams with the key insights they need.

With business intelligence, organizations will be able to ask questions such as:

“Which of our machinery have been in operation for over 10 years and are showing signs of production slowdown over the last 6 months?” “Which of our machines are producing heat and noise that are above our company protocol over the last 48 hours?”

In addition, with the right business intelligence in manufacturing, maintenance teams can be alerted to potential issues that need to be attended to when certain parameters are hit that are contributing factors to a downtime situation.

2) Better Optimize Your Supply Chain

From the purchasing of raw materials to the shipping of products to freight forwarders, the value chains of most manufacturing companies are filled with inefficiencies that add up.

On the supply side, manufacturing analytics & business intelligence can help leaders better understand:

- The cost of the component

- The component’s utilization efficiency

- The supplier’s delivery lead-times for each component

While on the delivery side, business leaders will gain a better understanding of:

- The cost & efficiency of their freight forwarding agents

- The pick-up timings from the warehouse

Through insights from the supply chain data, manufacturers will be able to better visualize their processes and learn where the inefficiencies lie.

This allows more precise control over costs, shipment timings, supplier and delivery expenditures, helping to lower overall costs for higher profitability.

3) Predict & Forecast Production Demand from Customers

One of the most challenging aspects of manufacturing is coming out with the correct demand forecast for products.

A successful prediction model or projection will allow manufacturers to fulfill production demands for their customers. This helps to generate higher revenue and further allows manufacturers to better schedule production runs for maximum profitability.

In addition, an accurate production forecast also allows decision-makers to better manage the cost of their raw materials as well as ensure there will be sufficient space in the warehouse to store the finished products.

This also helps to avoid overpaying suppliers for a sudden shipment of raw materials as well as reduces any instances of leasing third-party warehousing space to store additional products using business intelligence in manufacturing.

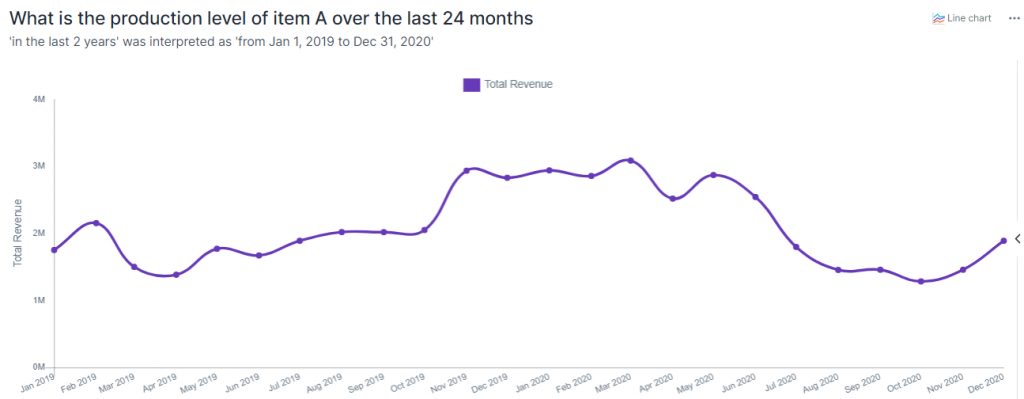

Utilizing business intelligence, manufacturers will be able to converse directly with their data to gain insights on their production history, combining both historical information and forward-looking data points.

They can ask questions such as

“What is the production level of item A over the last 24 months”

“Which of our production lines can handle an additional 10,000 units a day in December this

year?”

The insights gleaned will allow managers to make smarter predictions and formulate a data-driven plan of their production strategy.

Additionally, manufacturers will also be able to work together with retailers and share insights, from both the supply and demand fronts, to quickly capitalize on consumer trends to capture more sales and prevent any potential product shortages from happening.

4) Optimizing Your Pricing Strategies

As a manufacturer, your prices are perhaps one of the most crucial aspects you’ll need to optimize – as well as being the toughest due to the number of factors that influence them.

Give a quote too high, and you might lose the contract to other competitors that might outprice you. However, if your pricing is too low, you could very well be losing money with every item being manufactured.

Business intelligence in manufacturing allows connecting disparate data sources across your entire organization for a more holistic analysis of what the optimal pricing should be across your production line and schedules.

By connecting all datasets together and by enabling leaders to ask questions conversationally to their data, better pricing decisions can be made to optimize the revenue and profitability of each production run according to different unique scenarios.

5) Enables Better Warehousing & Inventory Management

Warehousing can be a challenge for manufacturers especially when other parts of the production process aren’t optimized.

In a world where many companies aspire to emulate a zero-inventory model and quick shipping is key, manufacturers must find a way to optimize their warehouse arrangements and the production flow coming into it.

From quality control checks and inventory accuracy to space utilization, manufacturers can easily utilize the power of business intelligence to quickly understand how to manage their warehouse better.

Key questions such as

“Which product types in our warehouse have the highest carrying cost of inventory?”

“What is the inventory turnover the last 12 months”

can be asked to gain critical insights into the state of operations of the warehouse.

This allows decision-makers to effectively optimize their inventory management for more effective warehouse operations.

6) Identify Production Trends for Better Marketing

Manufacturers rely on different streams of businesses for their income. Some products yield higher margins than others, while others require simpler manufacturing processes to get the job done.

With business intelligence in manufacturing, leaders will be able to identify products that yield the most profit while utilizing the least amount of production time.

This allows their marketing and sales departments to reach out to potential customers that might be looking to manufacture their high-margin products.

Unlock Value Across Your Manufacturing Operations with Business Intelligence Today

At Unscrambl, we believe in helping manufacturers optimize their operations to increase business productivity through the power of business intelligence.

Through Qbo, organizations will be able to gain insights into their data by simply asking questions conversationally for data-driven decision making.

Embark on a free 14-day trial today and start transforming your manufacturing operations for greater profitability.